The Ever-Evolving World of Metal Products: A Comprehensive Guide

Related Articles: The Ever-Evolving World of Metal Products: A Comprehensive Guide

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to The Ever-Evolving World of Metal Products: A Comprehensive Guide. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Ever-Evolving World of Metal Products: A Comprehensive Guide

Metal products are ubiquitous in our lives, from the humble can opener to the intricate components of a spacecraft. Their versatility, durability, and adaptability have made them indispensable across diverse industries, contributing significantly to technological advancements and societal progress. This article aims to provide a comprehensive overview of the vast world of metal products, exploring their applications, manufacturing processes, and the factors driving their continuous evolution.

A Spectrum of Metals: Properties and Applications

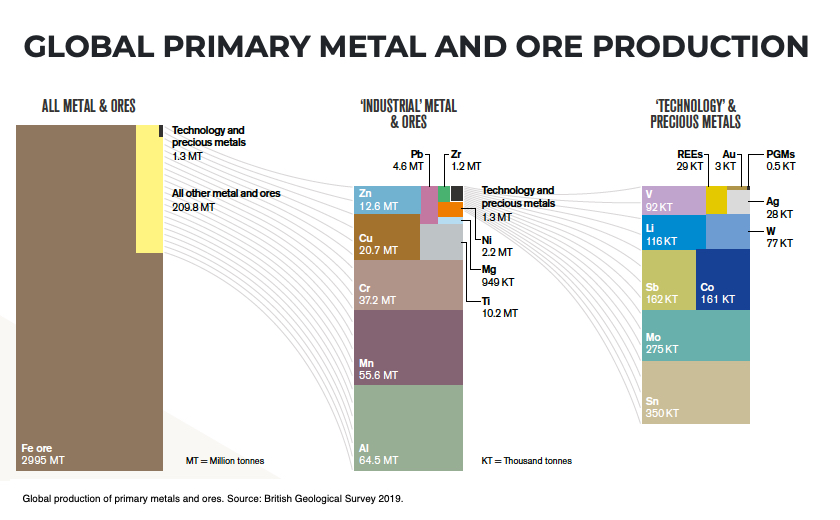

The world of metal products is as diverse as the metals themselves. Each metal possesses unique properties, including strength, malleability, conductivity, and resistance to corrosion, which dictate their suitability for specific applications.

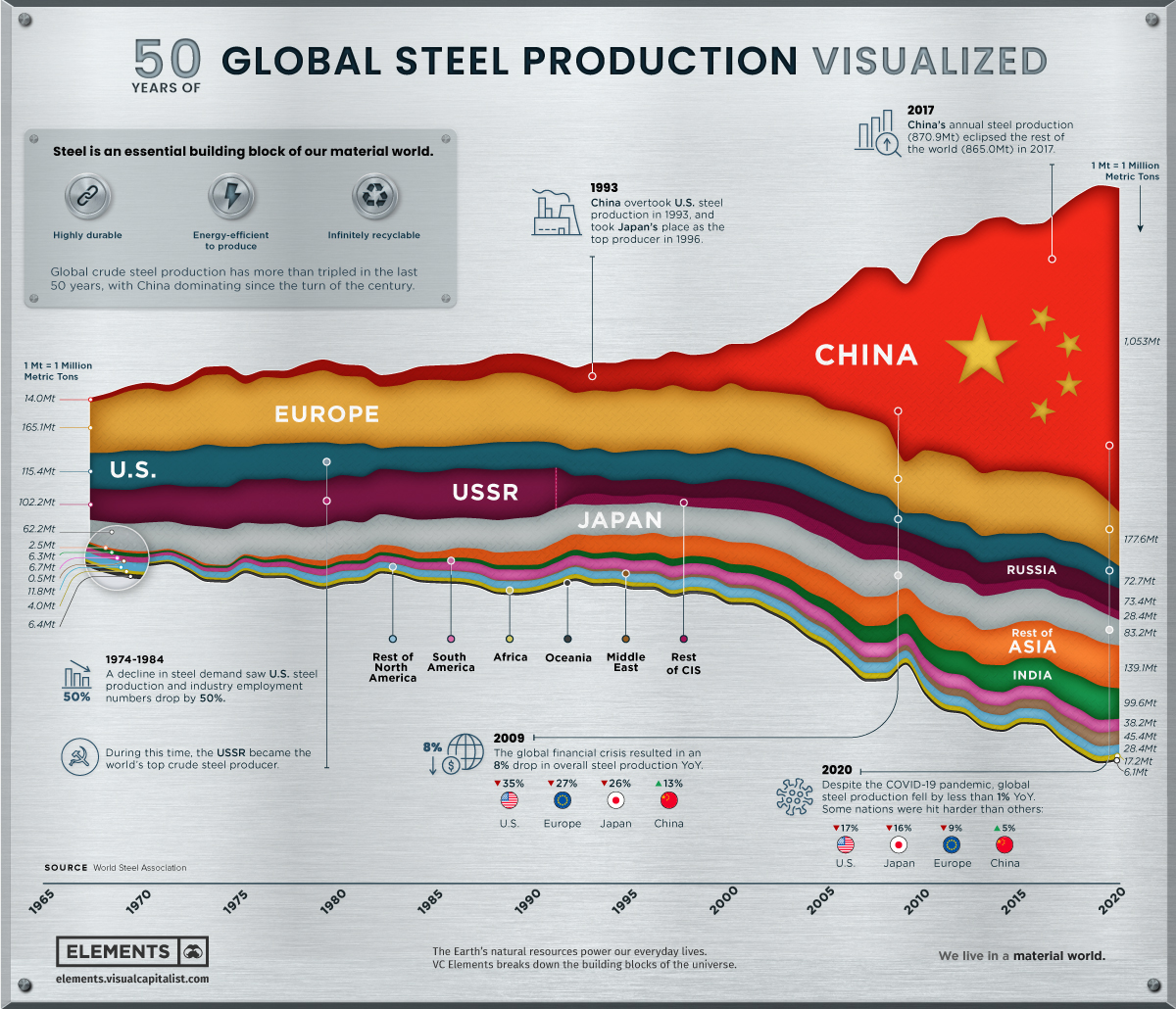

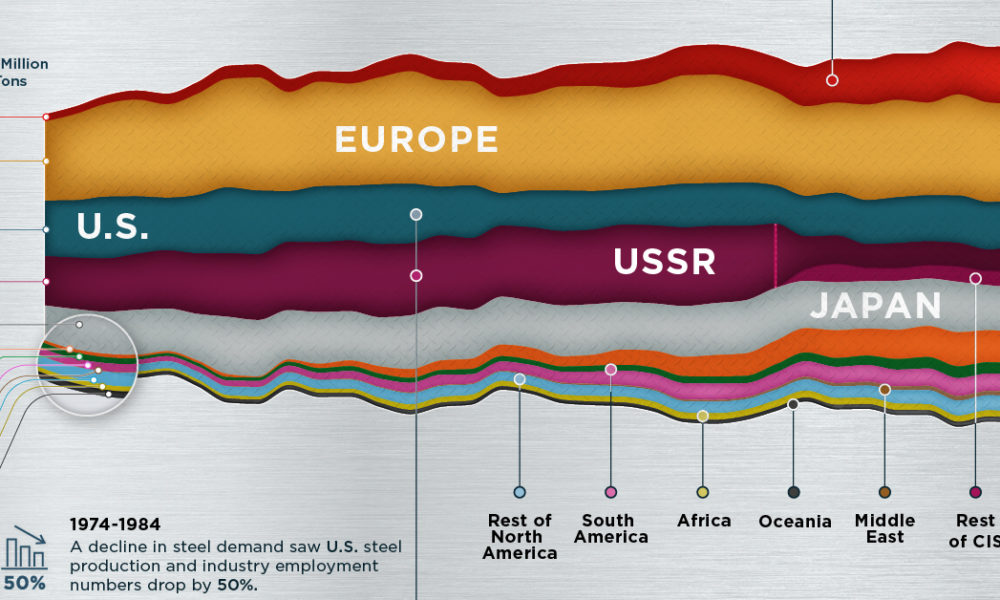

- Iron and Steel: These are the most widely used metals, known for their strength, durability, and cost-effectiveness. Steel, an alloy of iron and carbon, offers increased strength and versatility, making it ideal for construction, automotive parts, and infrastructure projects.

- Aluminum: Lightweight, corrosion-resistant, and highly conductive, aluminum finds applications in aerospace, automotive, packaging, and construction industries. Its recyclability further enhances its environmental appeal.

- Copper: Known for its excellent conductivity, copper is essential for electrical wiring, plumbing, and heat exchangers. Its antimicrobial properties also make it suitable for medical equipment.

- Titanium: Renowned for its exceptional strength-to-weight ratio and resistance to corrosion, titanium is used in aerospace, medical implants, and high-performance sporting goods.

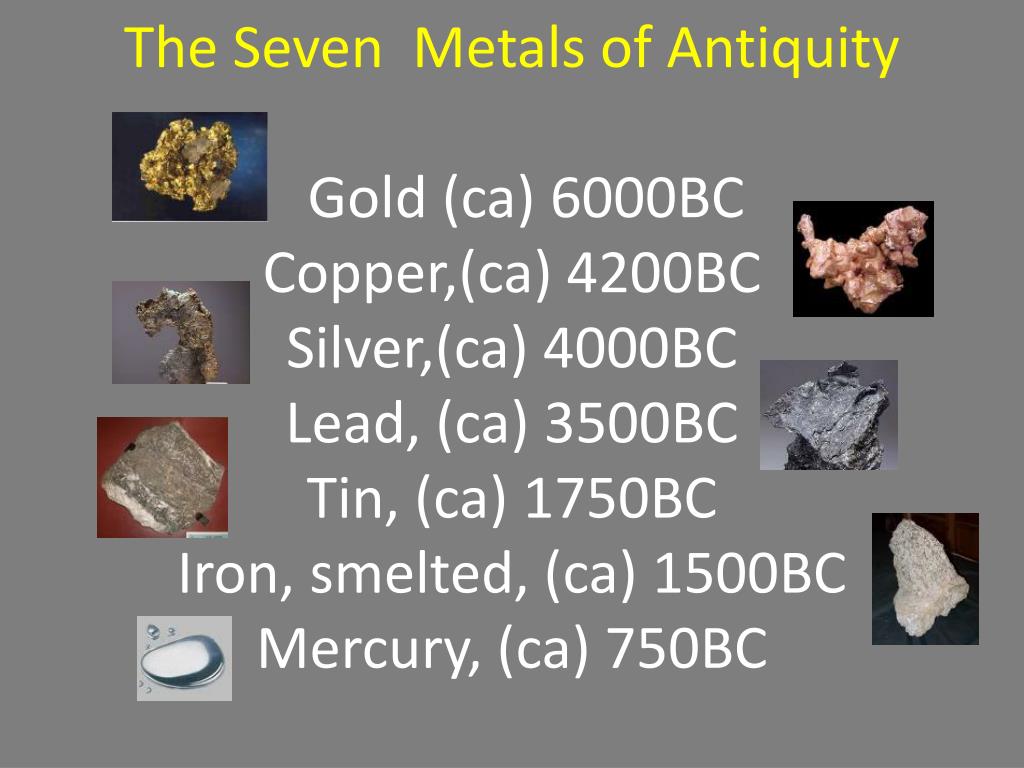

- Gold and Silver: These precious metals are prized for their beauty, inertness, and conductivity. They find applications in jewelry, electronics, and dentistry.

Manufacturing Processes: Shaping Metal into Products

The transformation of raw metal into functional products involves a range of sophisticated manufacturing processes, each tailored to the desired properties and applications.

- Casting: This process involves pouring molten metal into a mold, allowing it to solidify into the desired shape. Casting is suitable for producing complex shapes and large quantities of products.

- Forging: Metal is heated and shaped by hammering or pressing, resulting in increased strength and durability. Forging is used for manufacturing tools, automotive parts, and structural components.

- Rolling: Metal is passed through a series of rollers, reducing its thickness and creating sheets or plates. Rolling is essential for producing flat metal products used in construction, automotive, and packaging industries.

- Extrusion: Metal is forced through a die, creating a specific cross-sectional shape. Extrusion is used to produce pipes, tubes, and profiles.

- Machining: Metal is removed using cutting tools, shaping it into precise dimensions. Machining is used for creating intricate parts and achieving high levels of accuracy.

- Welding: Joining two or more pieces of metal using heat and pressure, welding is essential for creating durable structures and complex assemblies.

The Driving Forces of Innovation in Metal Products

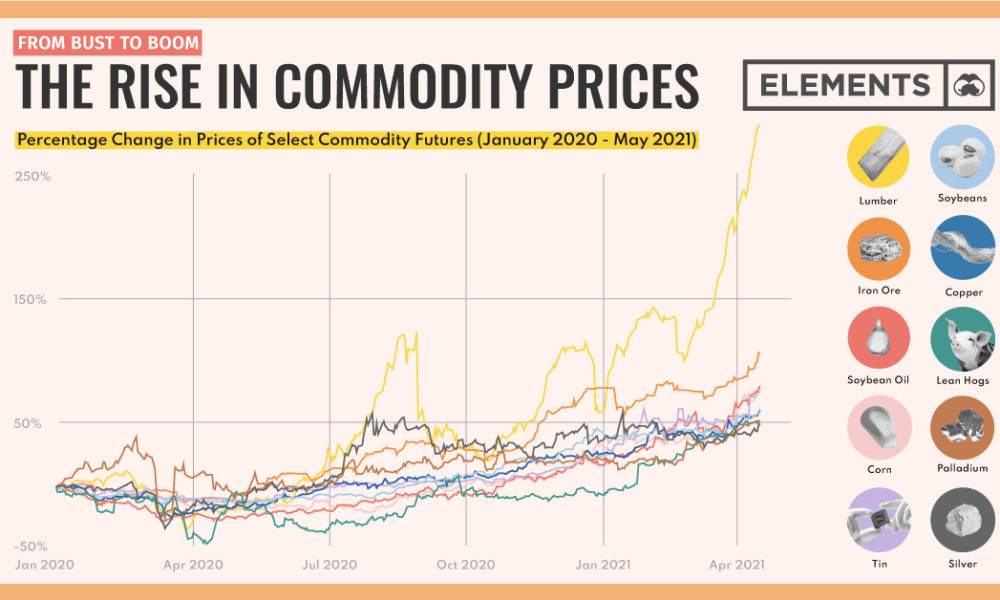

The world of metal products is constantly evolving, driven by technological advancements, changing consumer needs, and environmental concerns.

- Advanced Materials: Research and development in materials science is leading to the creation of new alloys with enhanced properties, such as high strength, lightweight, and corrosion resistance. These innovations are particularly impactful in industries like aerospace, automotive, and medical technology.

- Additive Manufacturing (3D Printing): This technology allows for the creation of complex metal parts layer by layer, enabling intricate designs and customized solutions. Additive manufacturing is revolutionizing the production of prototypes, tooling, and bespoke components.

- Sustainability: The environmental impact of metal production is a growing concern. Manufacturers are increasingly focusing on sustainable practices, including recycling, reducing energy consumption, and using eco-friendly materials.

- Emerging Applications: Metal products are finding new applications in diverse fields, driven by technological advancements and societal needs. Examples include metal-based energy storage solutions, advanced medical implants, and sustainable building materials.

FAQs about Metal Products

1. What are the benefits of using metal products?

Metal products offer a range of benefits, including:

- Durability: Metals are known for their strength and resistance to wear and tear, making them ideal for long-lasting applications.

- Versatility: Metals can be shaped into a wide variety of forms and sizes, catering to diverse design requirements.

- Conductivity: Metals exhibit excellent electrical and thermal conductivity, making them essential for applications requiring efficient energy transfer.

- Recyclability: Many metals can be recycled multiple times without losing their properties, contributing to sustainable manufacturing practices.

2. How are metal products made?

The manufacturing of metal products involves various processes, including:

- Casting: Pouring molten metal into a mold to create the desired shape.

- Forging: Shaping metal by hammering or pressing to increase strength and durability.

- Rolling: Reducing metal thickness through rollers to create sheets or plates.

- Extrusion: Forcing metal through a die to create a specific cross-sectional shape.

- Machining: Removing metal using cutting tools to achieve precise dimensions.

- Welding: Joining metal pieces using heat and pressure for durable structures.

3. What are the latest trends in metal product development?

The metal product industry is constantly evolving, driven by:

- Advanced Materials: Development of new alloys with enhanced properties.

- Additive Manufacturing (3D Printing): Enabling intricate designs and customized solutions.

- Sustainability: Focus on recycling, energy efficiency, and eco-friendly materials.

- Emerging Applications: Expanding into new fields like energy storage, medical implants, and sustainable building materials.

Tips for Selecting Metal Products

- Consider the Application: Determine the specific requirements for the product, such as strength, durability, conductivity, and corrosion resistance.

- Choose the Right Metal: Select the metal that best meets the application requirements, taking into account its properties and cost.

- Evaluate Manufacturing Processes: Understand the different manufacturing processes available and their suitability for the desired product.

- Prioritize Sustainability: Opt for products made from recycled materials or produced using sustainable practices.

- Seek Expert Advice: Consult with professionals in the metal industry for guidance and recommendations.

Conclusion: A Future Shaped by Metal

The world of metal products is a testament to human ingenuity and innovation. From the ancient tools of our ancestors to the advanced materials shaping our future, metals have played a pivotal role in human progress. As technology continues to evolve and societal needs change, the metal industry will continue to adapt, developing new materials, manufacturing processes, and applications that will further enhance our lives and contribute to a sustainable future.

:max_bytes(150000):strip_icc()/metal-alloys-2340254_final-ca186a30b3454d7d936ad12114d6cdd9.png)

Closure

Thus, we hope this article has provided valuable insights into The Ever-Evolving World of Metal Products: A Comprehensive Guide. We thank you for taking the time to read this article. See you in our next article!